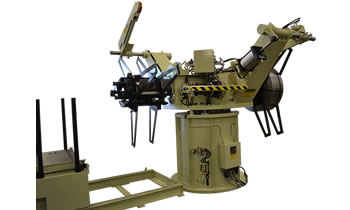

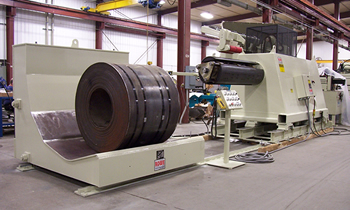

Coil Reels, Uncoilers & Stock Reels

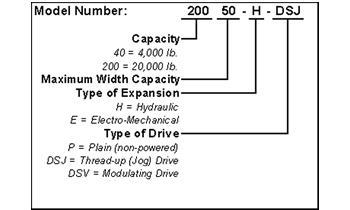

ROWE © 's coil stock reels and uncoilers range in capacity from 4,000 LBS. to 60,000 LBS. We offer two distinct styles of mandrel expansion for our coil reels; our standard hydraulic expansion and our original mechanical screw-type expansion. Our coil reels offer years of dependable service in the toughest of environments.

Rowe © offers two distinct designs of expansion, based on coil capacity, to meet your coil handling needs: the (3) Arm Link Pin Series, (4K to 10K Load Rating) and the Heavy Duty Sliding Wedge Series.

Our stock reels have the following drive configurations, based on customer preference and application requirements.

—P Plain Coil Reel

Plain Coil Reels are arranged for pull-off operation by having the mandrel equipped with a pneumatic drag brake with line regulator adjustment to provide a constant back tension during the pull-off operation. (Note: An electric drag brake or a spring set pneumatic brake can be supplied in place of the standard pneumatic brake if desired)

—DSJ Driven Spindle Jog Drive Coil Reel

The driven spindle jog drive reel is arranged for pull-off operation with the mandrel driven by a hydraulic motor for threading material from the mandrel to the next machine in line. The mandrel is equipped with an adjustable air brake for different weight coils. For very heavy coils, a laser brake control can be used to monitor the size of the coil and adjust the brake accordingly to ensure proper brake pressure at all times.

—DSV Driven Spindle Variable Speed Stock Reel

The driven spindle variable speed coil reel is arranged for slack loop payoff operation with the mandrel driven by an AC Motor coupled through an AC vector drive and controlled with standard laser loop control. Jogging controls for threading are also provided.

—DECR Double End Coil Reel

The double end coil reel can greatly reduce coil change over times, since the empty mandrel can be reloaded with a new coil while the press feed line is operating. A double end coil reel equipped with dual hold down arms is ideal for running partial coils.

Standard Features

- Single and Double End Configurations

- Coil Weight Capacities from 4,000 to 60,000 LBS.

- Standard Coil Diameter Capacity of 60"

- Coil Width Capacities from 18" to 72" (Model Dependant)

- Mandrels in Link Pin, or Heavy Duty Sliding Wedge Designs

- Coil Locating Scale in 1 Arm

- Set of Coil Keepers Standard w/ Each Mandrel

- Full Radius Mandrel Design (Option on Link Pin Models)

- Pneumatic Brake w/ Regulator (for —P, —DSJ)

- Powered Thread-up (Jog) Drive (for —DSJ)

- AC Open Loop Vector Drive w/ Laser Loop Control (—DSV)

Available Options

- Full Radius Mandrel Caps (on link pin style)

- Up to 72" O.D. Coil Capacity Coil Clamping Arm w/ Choice of …

- Non-Powered Roller (light duty. 4" minimum stock width)

- Powered Hold Down Wheel (6 in. minimum stock width)

- Powered Hold Down Rollers (24 in. minimum, for heavier duty applications)

- Narrow Powered Wheel (3½ in. minimum, for thinner, narrower applications)

- (4) arm mandrel design

- Secondary Floor Mounted Arms for Heavier Gauge Materials

- Laser Brake Tension Control

Hold Down Arms for Safety

Hold down arms provide added safety during the thread-up process. The coil clamping arm prevents clockspringing of the coil during both unbanding and coil thread-up.

A secondary arm is suggested in high yield or high gauge material applications for additional coil support and operator safety. The secondary arm is similar to the reel-mounted arm, but is positioned behind the reel to support the back of the coil.

Stock Reel Specifications

Stock Reel Specifications |

||||||

Series |

Range Coil Widths |

Max. Coil Weight Cap. |

Max. Coil O.D. |

Mandrel I.D. Range |

No. of Arms |

Expansion Type |

4000 |

18" & 24" |

4,000 lb. |

60" |

13" to 17" |

3 |

Manual Hand Crank Expansion (Optional Hydraulic Expansion) |

6000 |

18", 24", & 30" |

6,000 lb. |

60" |

13" to 17" |

3 |

|

8000 |

18", 24", 30", & 36" |

8,000 lb. |

60" |

13" to 17" |

3 |

|

10000 |

24", 30", 36" & 48" |

10,000 lb. |

60" |

17" to 21" |

3 |

|

15000-H |

24", 36", 48", & 60" |

15,000 lb. |

60" |

19½" to 24½" |

3 |

Hydraulic Powered Expansion |

20000-H |

24", 36", 48", 60", & 72" |

20,000 lb. |

60" |

19½" to 24½" |

3 |

|

30000-H |

24", 36", 48", 60", & 72" |

30,000 lb. |

60" |

19½" to 24½" |

3 |

|

40000-H |

48", 60", & 72" |

40,000 lb. |

60" |

19½" to 24½" |

3 |

|

50000-H |

60" & 72" |

50,000 lb. |

60" |

19½" to 24½" |

3 |

|

7500-E |

20", 30", & 40" |

7,500 lb. |

60" |

15¾" to 20¼" |

4 |

Electric Screw-Type Expansion |

10000-E |

20", 30", 40", 50", 60" |

10,000 lb. |

60" |

15¾" to 20¼" |

4 |

|

12000-E |

30", 40", 50", 60", 72" |

12,000 lb. |

60" |

19½" to 24½" |

4 |

Electric Screw-Type Expansion |

16000-E |

30", 40", 50", 60", 72" |

16,000 lb. |

60" |

19½" to 24½" |

4 |

|

20000-E |

30", 40", 50", 60", 72" |

20,000 lb. |

60" |

19½" to 24½" |

4 |

|

30000-E |

40", 50", 60", 72" |

30,000 lb. |

60" |

19½" to 24½" |

4 |

|

40000-E |

50", 60", 72" |

40,000 lb. |

60" |

19½" to 24½" |

4 |

|

50000-E |

50", 60", 72" |

50,000 lb. |

60" |

19½" to 24½" |

4 |

|