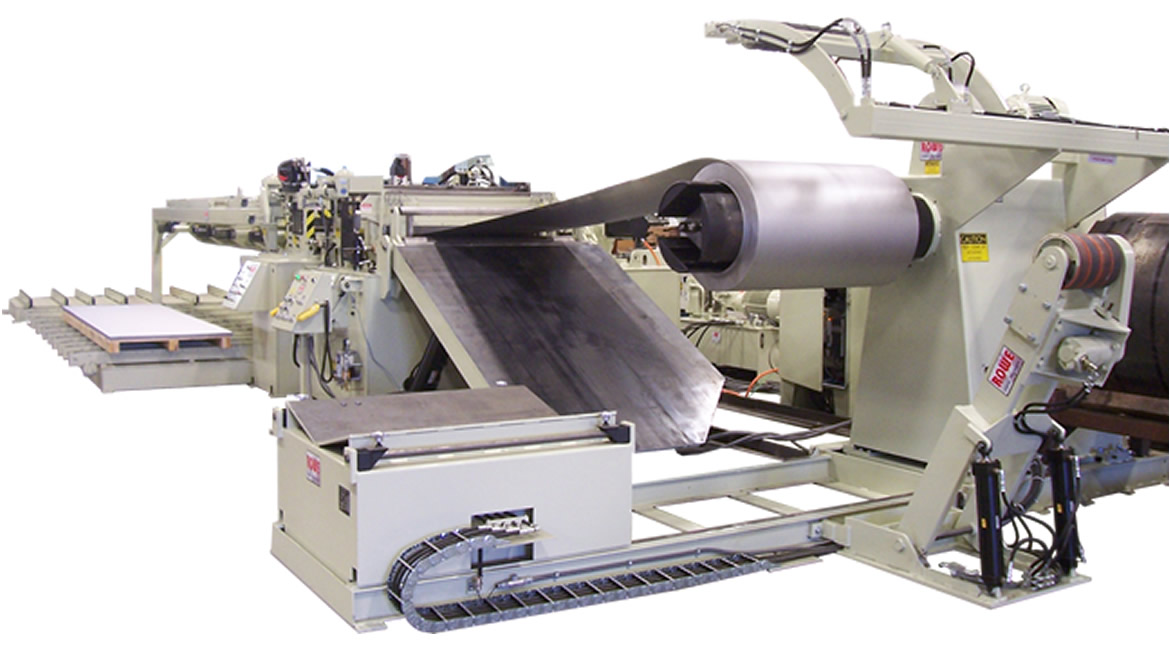

Coil Cradles

ROWE© started in the coil handling business in 1950 with its very first "Easy Load" coil cradle.

Coil Storage

ROWE© offers a variety of coil storage devices to fit virtually any application.

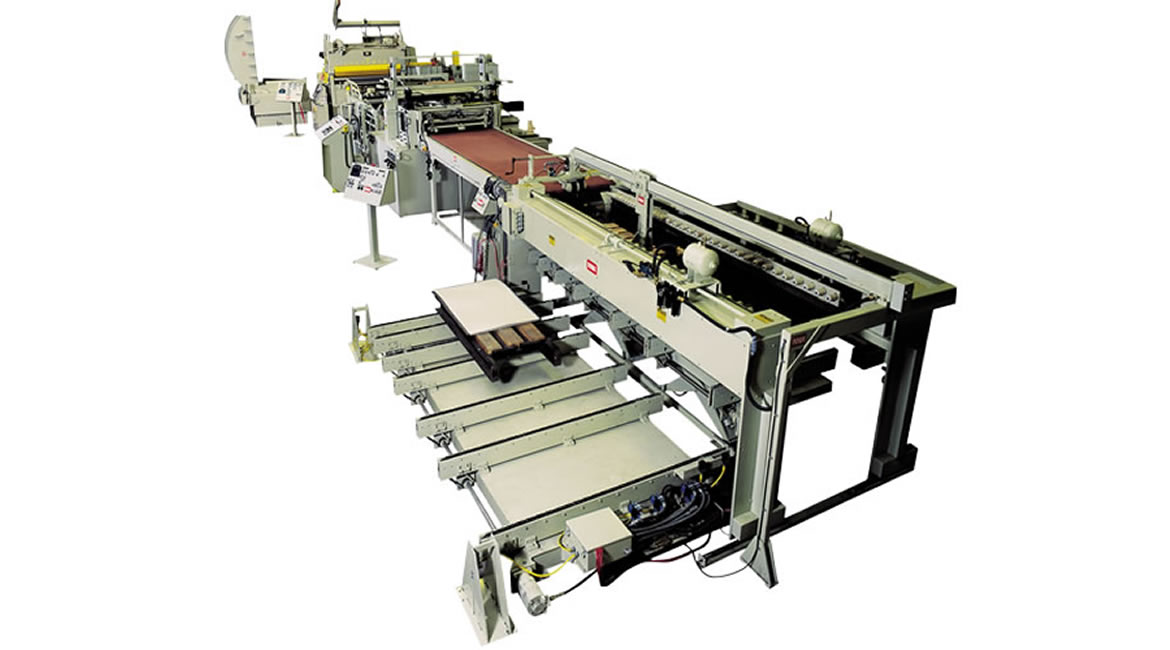

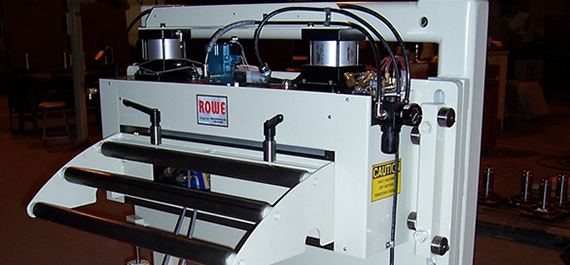

Press Feeds

Our Press Feed systems are designed to meet the toughest requirements of our customers.

Special Equipment

We will work with you to understand your needs, from Parts Straighteners to Scrap Choppers.

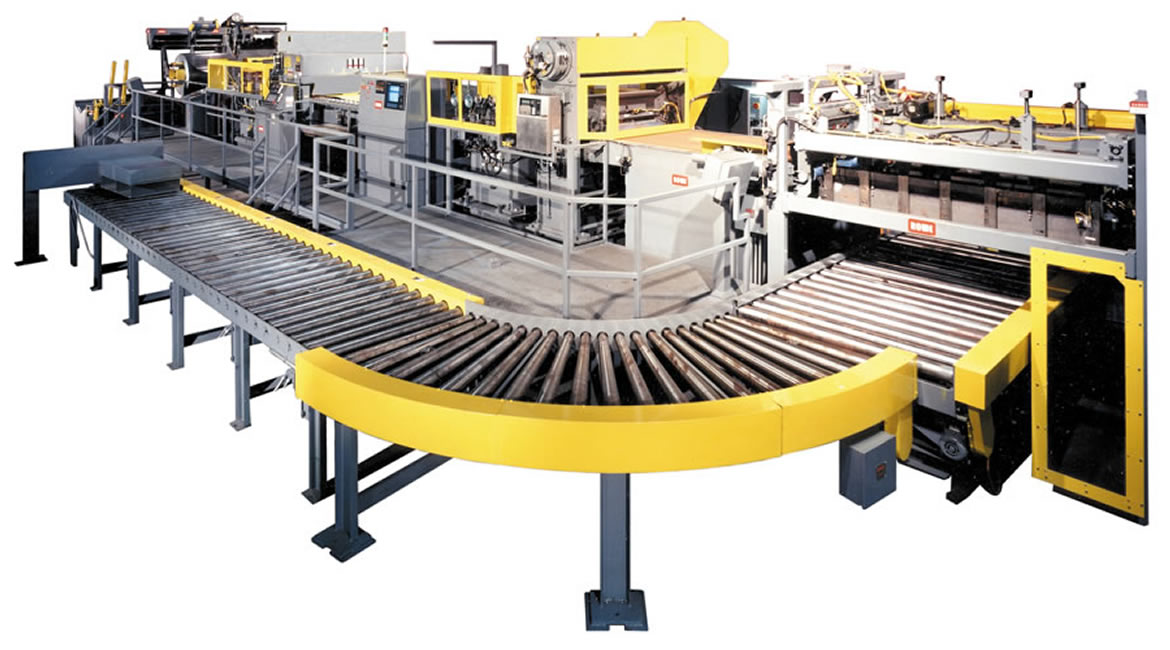

Combinations

ROWE©'s Space Manager is ideal for heavier gauge applications in limited space conditions.

Servo Feeds

ROWE© offers high performance fully backed up four-roll Servo Feeds for superior feed length accuracy.

Double Reels

ROWE© single and double end Coil Reels provide the best I.D. support and payoff control.

Service

Our Service Professionals offer preventative maintenance as well as emergency service.

Read MoreCustom Engineering

We have well over 100 years of experience within our Engineering Department.

Read MoreServo Feed Control Retrofits

Have an older machine that you'd like to speed up or improve it's capabilities?, we can help!

Read MoreParts

We keep over 10,000 replacement parts in stock, most parts can be shipped the same-day.

Read More

ROWE© Machinery — Experience Matters

Organized on June 1, 1950. Harper Rowe, owner, was named President; Tom Gray, Executive Vice President; Everett Reed, Vice President and Sales Manager; and Frank Ward, Secretary-Treasurer.

read moreWe are Hiring

Please follow the link below to see all of our current job openings:

Please follow the link below to see all of our current job openings:

Employment listings for Formtek-Maine on Jobs in ME.

A rare opportunity has opened for a Midwest Regional Sales Manager

Formtek-Maine Brands

What this means to you is that you not only have the power of World Class support and service from ROWE©, but also that ROWE© is able to leverage the pooled resources of some of the most recognized names in the coiled metal processing industry.

Our leadership is recognized

As a result of preferred supplier agreements with various OEMs, Formtek-Maine has been offering coil line products and solutions from ROWE©, and other Formtek-Maine brands for many reliable years

Company Mission/ Vision

Mestek's machinery division serves the manufacturing community with decades of metal forming experience. The Mestek machinery division truly reflects our core principle of "Experienced Based Innovation".

We're here for you!

Service Excellence

If the unforeseen happens and you require service on your ROWE© Equipment, our highly trained service team stands ready to assist you.

With our factory trained team of experienced Field Service Technicians at the ready to assist you, uptime is maximized. Whether it's an equipment failure or you just need an equipment evaluation, ROWE© has your back.

Mr. Robert Kirk Field Service Manager, Formtek-Maine.

When you are down and you need an in-stock part shipped overnight, ROWE©'s parts department stands ready to serve you. We also carry a complete line of consumable items for our equipment.

Mr. Dennis Weymouth Parts-Traffic Manager, Formtek-Maine.

Our extensive dealer network; supported by our Regional Sales Managers and the factory, provide you with unparalleled application support. Call us today! to find out what ROWE© can do for you!

Mr. Kevin Enos National Sales Manager, Formtek-Maine.

Whether you need a 6” Servo Feed or a large 84” cut-to-length line or anything in between, we have the experience and knowledge to get you the right equipment at the right price for your application.

Mr. Craig Derosby Senior Sales Engineer, ROWE© Machinery & Manufacturing.